Hong Kong designer Dennis Cheung visited the factory; collaborative product development between Hong Kong and Japan to be realized in “DESIGN INSPIRE” in 2024.〜Hirata Tile Co.,Ltd/Nakai Sangyo Co., Ltd/Studio RYTE〜

2024.11.09

CONTENTS

Collaboration between Japanese manufacturing companies and Hong Kong designers

DESIGN INSPIRE” is coming up on December 5-7, 2024. Preparations are steadily underway at the booths of Japanese companies. The highlight of this year’s event is a product collaboration project between Hong Kong designers and exhibiting companies. Prototypes developed by each company in collaboration with Hong Kong designers will be presented on the day of the exhibition.

Mr. Dennis Cheung, a creative designer in Hong Kong, will visit Japan in early October. He visited the respective factories of exhibiting companies, Hirata Tile Co.,Ltd. andNakai Sangyo Co., Ltd. to share the production process. We spoke with him about his thoughts and insights into Japanese craftsmanship.

●Dennis Cheung/Studio RYTE

A design office that provides services for branding and projects utilizing architecture, interior design, and furniture. Dennis Chen’s focus is on design and environmental impact. Working with clients, the firm strives to maintain beautiful creativity while being environmentally conscious.

To Tajimi City, Gifu Prefecture, the birthplace of glazed porcelain mosaic tiles

Tajimi City, Gifu Prefecture, is the birthplace of glazed porcelain mosaic tiles and boasts the largest tile production area in Japan. Tajimi City accounts for 90% of domestic production of mosaic tiles. Hirata Tile Co., Ltd. has a factory in such a “sacred place” for tiles. Mr. Dennis was impressed by the high level of creativity.

●Hirata Tile Co.,Ltd

The company purchases tiles and housing equipment from domestic manufacturers and provides comprehensive services from sales to installation. The company also focus on planning and developing its own brands, and in recent years the company has been proposing unique tiles and water-related products imported from overseas, mainly from Italy, France, and other European countries.

―Impression of Hirata Tile’s Factory in Tajimi?

Dennis: Having had the privilege to visit Hirata Tile’s factory in Tajimi, I was truly impressed by the attention to detail and the pristine organization of the facility. The ambiance exuded a sense of precision and dedication that is characteristic of Japanese craftsmanship. Witnessing the labor intensive yet meticulous handpicking of mosaic tiles in action left me in awe of their commitment to excellence.

― Important Aspects of Collaborating with Hirata Tile?

Dennis: When considering collaboration with Hirata Tile, the access to their unique tile-making techniques and cutting-edge & sustainable technologies is paramount. The opportunity to tap into their wealth of knowledge and expertise in ceramic in Gifu area can greatly enrich any collaborative project, fostering creativity and pushing boundaries in design. By leveraging their specialized skills, one can create exceptional and distinctive pieces that stand out in the market.

― Differences in Manufacturing Between Japan and Hong Kong/China?

Dennis: A notable difference I observed in manufacturing practices between the two lies in the scale and specialization of factories. Japanese facilities tend to focus on a specific expertise, honing their skills to perfection in a niche area. In contrast, Chinese factories often encompass a broader spectrum of trades and tasks under one roof, accommodating a range of production processes. This difference in approach reflects the diverse industrial landscapes of both regions, each offering distinct advantages and challenges.

Visit the main Plant in Wakayama, the birthplace of Kishu lumber

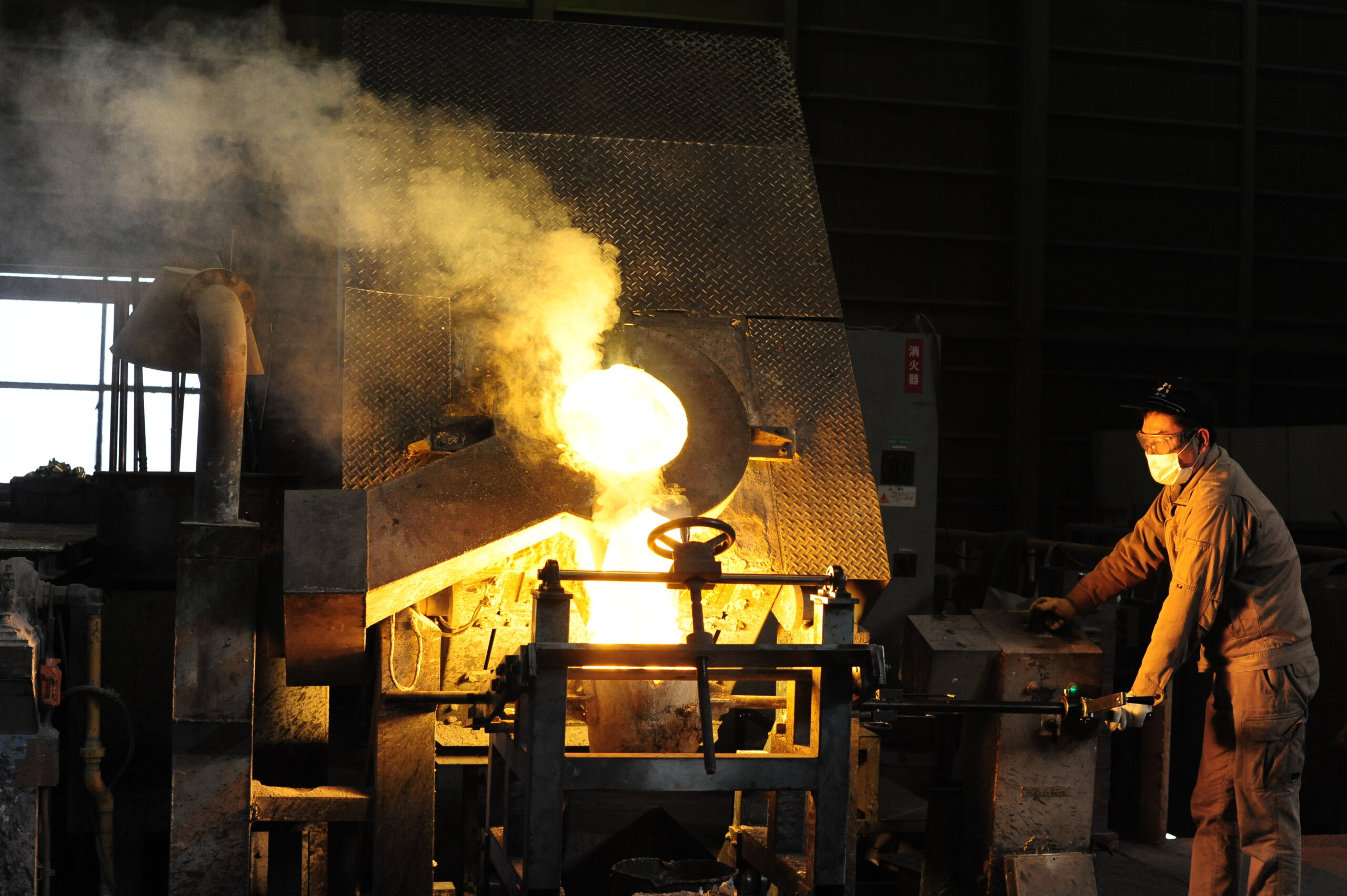

Next, we visited the main factory of Nakai Sangyo Co. The factory, which handles high-quality natural wood from Japan, is an open space filled with the aroma of wood. All wood processing processes up to commercialization are carried out here. Original brand “KITOTE” shoji screens are also manufactured here.

●Nakai Sangyo Co., Ltd

A general woodworking manufacturer with a factory in Wakayama, the birthplace of Kishu lumber. The company mainly handles wooden fittings such as shoji screens, doors, and Shinto shrines. While cherishing the proud craftsmanship of its craftsmen, the company is also engaged in the study of both hand and machine processing to deliver high-quality wood products to the world.

https://www.nakaisangyo.co.jp/

― Impression of Nakai Sangyo’s/Kitote Factory?

Dennis: My experience at Nakai Sangyo’s Kitote factory was nothing short of inspiring. The craftsmanship displayed by the artisans was exemplary, characterized by a deep-rooted dedication to their craft and an unwavering commitment to perfection. The level of attention to detail observed in their work is a testament to their mastery and expertise, earning them well-deserved respect within the industry. The way how they made Kumiko and Shoji screens sets a high standard for quality and artisanship.

―Key Considerations for Collaborating with Nakai Sangyo.

Dennis: When contemplating a collaboration with Nakai Sangyo, it is essential to embrace an open-minded approach that values the fusion of traditional techniques with a cross-cultural perspective. By recognizing and respecting their heritage while also bringing fresh perspectives and innovative ideas to the table, a harmonious and fruitful collaboration can be achieved. This blend of tradition and modernity can lead to the creation of truly unique and culturally rich designs that resonate with a global audience.

―What have you learned through the collaboration project after visiting both plants?

Dennis: The collaboration project provided invaluable insights into the ethos of the Japanese manufacturing industry and reinforced the significance of unwavering belief and dedication in achieving project goals. Managing a project across different locations in Japan and Hong Kong within a tight timeframe presented its share of challenges, but it also underscored the importance of effective communication, meticulous planning, and a shared vision. With the help of Mr. Mori Seiki, the experience highlighted the power of collaboration in transcending geographical boundaries and cultural differences to deliver exceptional results.

―Expectations and Enthusiasm for Design Inspire.

Dennis: I am eagerly anticipating Design Inspire as a platform that fosters innovative crossovers and opens up new avenues for business growth and creative opportunities. The prospect of collaborative ventures among designers from different countries, particularly with Hong Kong designers, is immensely exciting. I believe that such collaborations have the potential to spark fresh ideas, drive cultural exchange, and propel the design industry forward. I look forward to witnessing the synergies that emerge from these interactions and the inspiring creations that result from such dynamic partnerships.

Outline of the event

DESIGN INSPIRE

Date & Time:December 5-7, 2024

Location: Hong Kong Convention and Exhibition Centre

organizing: Hong Kong Trade Development Council

cooperation: Japan Building Materials Association、Kansai Bureau of Economy

website: https://designinspire.hktdc.com/