Realizing a Bidirectional Exchange with a Cultural Fusion of Design

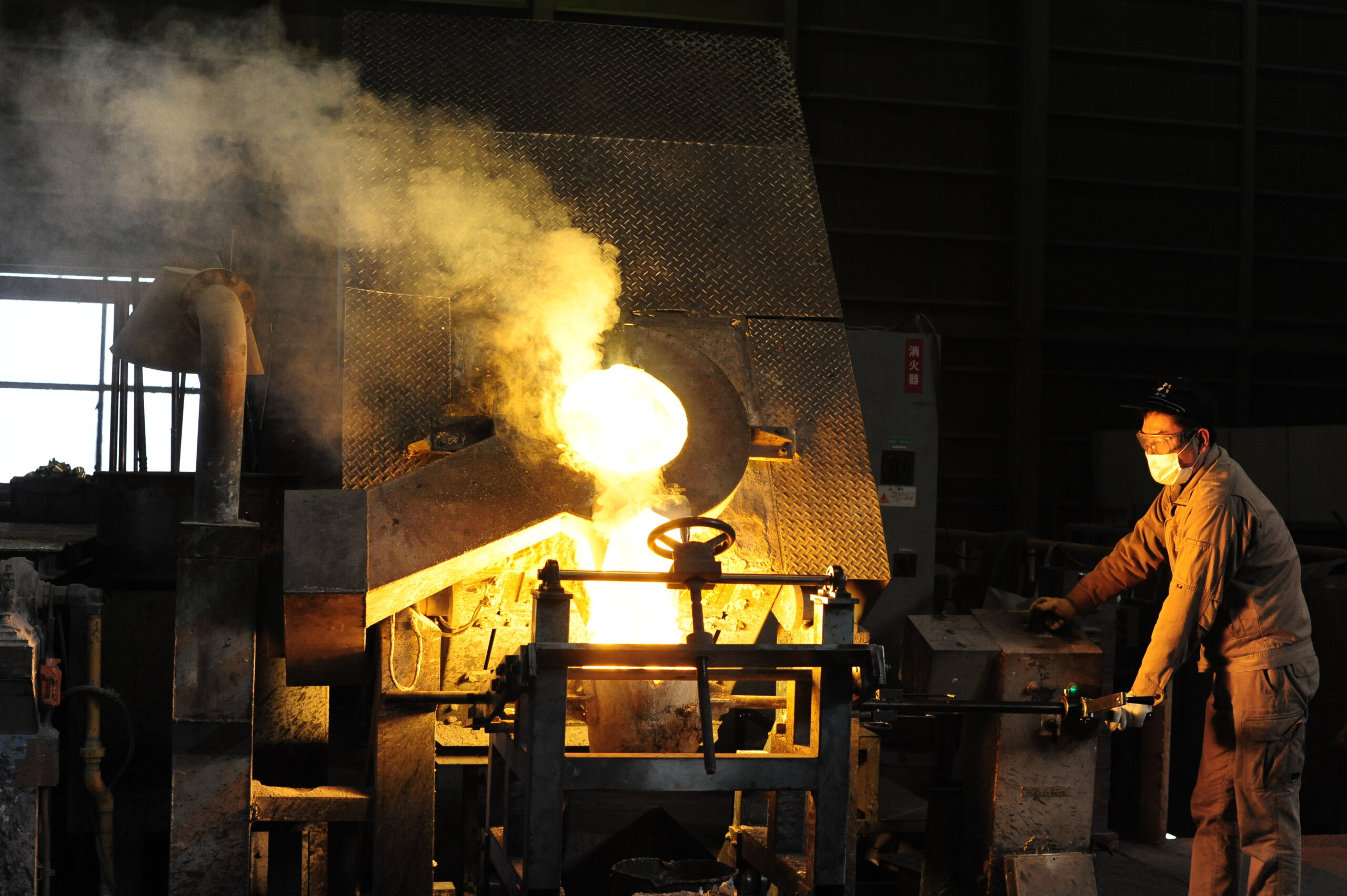

Aluminum liquified at 727 degrees is poured into a sand mold. 5 seconds, 10 seconds, 15 seconds. Once it’s finished being poured, the mold is moved to the kiln and the liquid metal is replenished before being poured again. The silver-colored liquid solidifies in about 20 minutes. This will become a prototype for a new door handle. In the middle of a large workshop, other craftspeople fill a wooden mold with sand before pressing weight down onto the joined-together mold. Each of the craftspeople’s rhythmical, flow-like movements have a purpose. One does not grow bored simply watching them work in their constant rhythm.

Aluminum melted at high temperature.

The manufacturer UNION Co., Ltd. (hereafter Union) entrusts its cast-metal production to is located in Takaoka, Toyama Prefecture. Takaoka is a region historically known for its traditional industries of producing Takaoka Buddhist altars and Takaoka copperware. They have cultivated both the artistic elements of Japanese painting required for manufacturing Buddhist altars, and the advanced casting techniques which express a delicate elegance. They strive to be rid of the idea of “good enough”. Paying attention to the small details leads to true value. The skilled casting artisans laugh and say they are simply doing what’s obvious, but the tranquil beauty of their finished products compares to no other.

Union is a door handle maker that has represented Japan since its founding, for more than 60 years now. We hold 90% of domestic shares and boast more than 3,000 types of manufactured goods being developed. We utilize a wide range of materials and offer a vast variety of shapes and sizes. That’s why we cooperate with a large number of manufacturers to create hardware as a fabrication facility-less (fabless) enterprise. By ascertaining the strengths and fields of expertise of each manufacturer and matching construction to design, we are able to provide top-quality products to the world.

Push a model of a door handle into the sand to create a shape.

We have also collaborated numerous times with architects and artists to hold exhibitions and reception events. Our new product on display at DesignInspire Hong Kong 2021 was made in collaboration with interior designer and Hong Kong native Keith Chan. At the age of 26 Keith established the design studio hintegro, which inherits Hong Kong’s cultural diversity while assertively adopting Japanese furniture, building materials and interior items.

When Keith visited Japan in 2019, he also visited the UNION showroom. After seeing and resonating with UNION’s method of working closely with designers to create hardware, Keith decided he would like to make a door handle using UNION’s unique stone blast technique and his own design.

Liquefied aluminum is poured into the mold.

“Bamboo is a popular plant in both Japan and Hong Kong, and it represents ‘good being’ and ‘good behaviour’ in Chinese culture.”

Bamboo was chosen as the base design element for Keith’s door handle. It became an item expressing Keith’s unique sensibilities while fusing together Hong Kong and Japanese cultures and sensitivities. Because of the COVID-19 pandemic, all meetings were held online. 3D data was created at UNION based on sketches, and a prototype was made using 3D printing. We worked together on each part of the process and discussed opinions until the materials and details were just right, culminating in the final design. About half a year was needed to complete the project. Our efforts produced a jointly developed piece that was deeply satisfying for both Keith and UNION. The current exhibition marks the first public showing for the piece.

(Left) Keith Chan, Founder, Hintegro; (Right) Junzo Tateno, President/CEO, Union Co.

The physical distance between nations is no longer an obstacle. Rather, it is precisely because of our different cultures that we can produce something unprecedented together.

UNION’s desire to work with architects and designers from around the world is indicative of our stance on design and craftsmanship

says Junzo Tateno, President of UNION Co., Ltd. Mr. Tateno serves as president of the company, but also works as Chief Executive of design. ArtWare, a commonly shared concept at our company, fuses the spirit and craftsmanship of art and hardware to create a unique concept at UNION.

“When creating new products, we at UNION strive to convey our intentions. By understanding the sense of beauty cultivated by architects and designers, and proposing projects that go beyond their expectations, we are greeted by the emergence of even greater creativity,” says Mr. Tateno.

After the aluminum has cooled and hardened, the products are removed from the sand mold.

Our love for making things is second to none. From the viewpoint of the advancements of technology in Japan, it is sometimes possible to ask the impossible of craftspeople and manufacturers. But that is all in the service of an uncompromised craftsmanship. Value is born from a correspondence between values. Something called impossible after it is made is a sign of respect for the artisans. Building elevating relationships with craftspeople will eventually also lead to the transfer of craftsmanship skills to the next generation. It is UNION’s task to maximize the value of our products by standing between the ideas of architects and designers and the technical skills of craftspeople.

The process behind the creation of door handles is truly a story worth telling. UNION’s ArtWare concept is always looking to the future, and to broader horizons. Our adventure is just getting started.